FIS Position and Support on Inflation and Material Shortages

The past two years have, without doubt, been some of the hardest times businesses in the finishes and interiors sector have faced. Uncertainty and challenge continues into 2023.

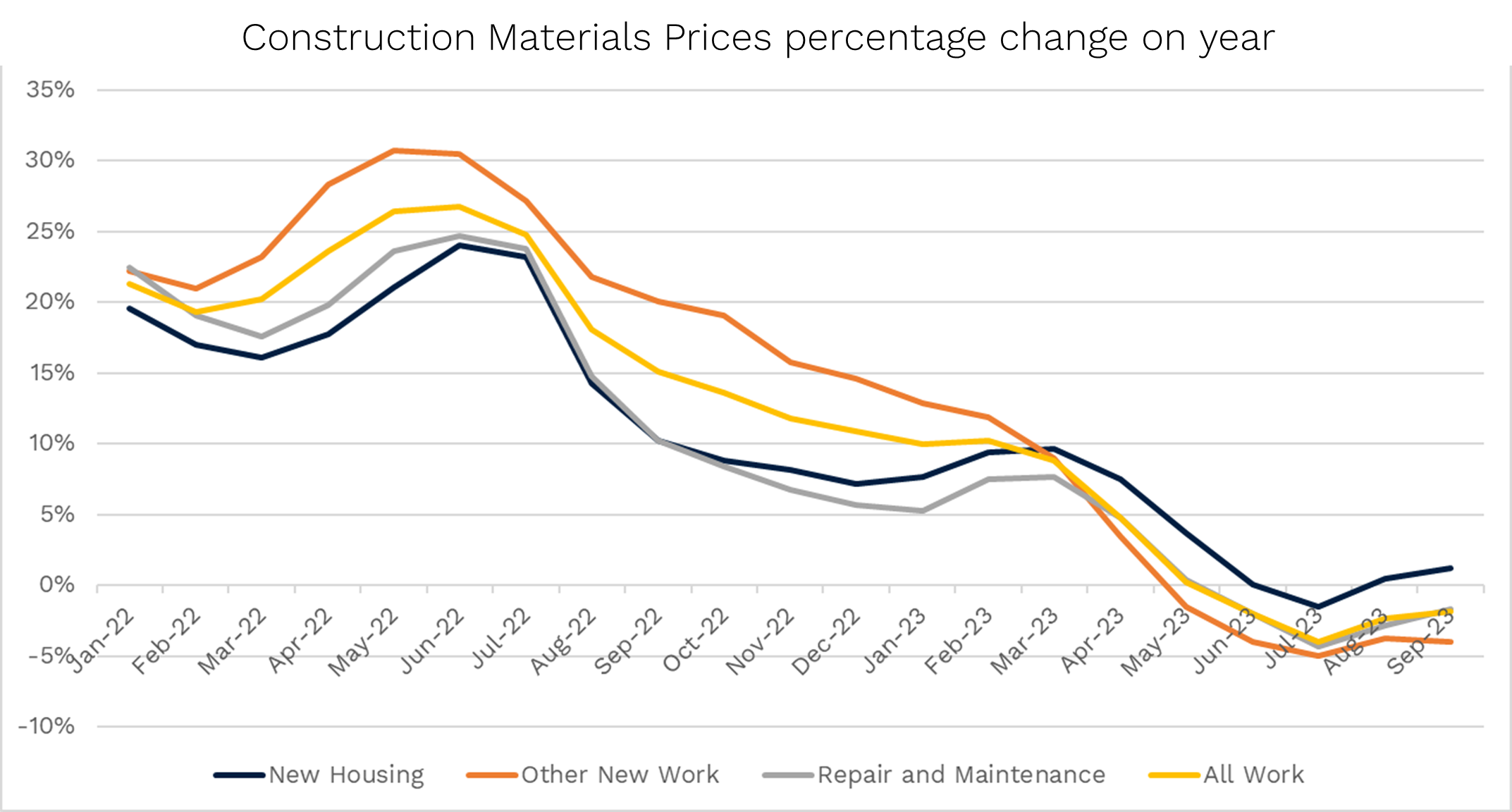

The underlying trend began post COVID with the RICS reporting construction materials costs in the UK had already reached a 40 year high based on the annual growth of the BCIS Materials Cost Index by the end of 2021. According to Joe Martin, BCIS Lead Consultant “The pressure on materials prices and availability is expected to continue at least until the end of 2022. Labour shortages are expected to evolve as the significant driver for overall construction cost increases next year and the construction sector would need to compete for it with other sectors”.

After this rapid inflation in 2021 across all material groups, 2022 started with concerns around the impact of ongoing labour shortages and the escalation of tragic events in Ukraine put further pressure on energy and fuel prices adding to pressure on the supply chain. This has resulted in the announcement of further price increases throughout 2022 and rapid inflation for key materials, fuel and energy. Of particular concern for FIS members are increases in insulation, steel and plasterboard.

The Construction Products Association have prepared for FIS Members an update on the wider impacts of this tragic conflict.

Keeping an eye on your contracts

Where this impacts existing contractual relationships members are reminded to check contractual terms and consider the relevance and application of any fluctuation clauses. If you are unable to rely on standard fluctuation clauses, an early conversation with your client in terms of your ongoing ability to fulfil the contract in the wake of rapid and unexpected price increases is essential.

Where you are currently tendering, consider carefully the impact of the current inflationary environment, look to link any fluctuation to material and product prices rather than general inflation or ensure that quotes are time stamped and limited. Where you cannot negotiate a shared risk approach with your client, you need to seriously consider what could worse case scenario mean to your business if prices drifted?

We encourage all in the construction sector to consider seriously the impact of imposing fixed prices at this time. The sector is working on every tighter margins and this could impact the resilience and ongoing viability of of businesses in the supply chain. Where concerns are raised, a pragmatic, understanding and collaborative approach is essential. It is vital that we work together to avoid conflict and we further encourage all companies to consider signing and adopting the principles set down in the Conflict Avoidance Pledge that has be developed by the Royal Institute of Chartered Surveyors (RICS) and endorsed by the Construction Leadership Council (CLC).

Below we provide some information on the market forces that are resulting in ongoing inflationary pressures and additional advice and guidance related to managing businesses and contracts in a high inflation environment.

The aim is to keep it refreshed so our members are have a clear picture and can have informed decisions up and down the supply chain.

When can we expect an end to all of this?

Whilst the rate of inflation is expected to slow in 2023, the situation remains volatile. With such a perfect storm of complex and cumulative issues it is difficult to know when we will start to notice improvement or how much worse things may get. The old adage hope for the best, but prepare for the worst comes to mind.

The FIS is an active participant in the Construction Leadership Council who continue to monitor the situation through a dedicated working group of subject experts – you can access the latest Construction Leadership Council Product Availability Statement here.

Energy Prices and Other Global Issues

As we step into 2023 the tragic events in Ukraine continues to impact oil and gas prices and hence energy costs across the world into a period or rapid inflation which is now feeding through into the price of construction products and logistics. In the period 1 April 2021, wholesale gas had risen from around of 50p/therm to around £2.80/therm by the end of March 2022.

You can track natural gas prices here.

Whilst the UK in not overly reliant on Russia or Ukraine for construction products (which together account for just 1.2% of imports of construction products, some areas such as flat glass and certain timber products have a more significant share from these markets. Projects could also be impacted by shortages of products such as concrete reinforcing bars or other unrelated shortages (such as bricks) which are still ongoing.

The global situation remains volatile and it is impossible to predict accurately the ongoing impact on material and product prices. Beyond the escalation in Ukraine, tension between the US and China and genuine concerns about UK Conformity Assessment (UKCA).

Logistical and Freight Challenges

Beyond supply and demand, inflation and availability problems has been further compounded by a number of issues related to freight and logistics, in 2021 we had the Suez Canal logjam, Brexit and pandemic uncertainty. An ongoing shortage of lorry drivers has also been reported and has put upward pressure on transport costs. Whilst shipping freight prices did ease in 2022, the invasion of Ukraine has pushed up fuel prices.

Squeezing the supply chain

A key concern is that in the wake of double digit inflation in the price of some materials and increasing labour costs and despite an increasingly healthy pipeline, we are not seeing equivalent inflation in tender prices, which means margins are likely to be squeezed and in extreme cases businesses could be driven into recession.

The latest tender price reports from MACE is showing that current tender price inflation ran at 7.5% in 2021 and were expected to rise by 5.5% in 2022, this is below the rate of inflation.

How can I track and report price movements?

There isn’t currently an index of prices specific to products in the Finishes and Interiors Sector, but you can draw out the main material movements via the Office of National Statistics, note this is lagging and prices are changing fairly rapidly at the moment. It also doesn’t necessarily reflect prices on the ground due to specific grades/distribution buffering etc.

The World Bank commodity price index and London Metals Exchange give a high level picture, but doesn’t get into the detail on products used in the finishes and interiors sector.

The RICS publish the annually the BCIS Material Price Index

Probably the best reference is via the merchant groups, for example :

For the sake of balance, if you publish a similar index, please don’t hesitate to pop a link over by email or in the chat and we’ll include it here.

FIS track labour prices on a half yearly basis with information available to contributors. If interested in learning more email iainmcilwee@thefis.org.

Top tips for contracting in a high inflationary market

FIS have produced a new factsheet for members looking at some standard clauses to include with quotations and top tips for contracting at a time of high inflation.

Build UK have also produced information to inform the entire supply chain on how to manage relationships in an uncertain inflationary environment

Bring your concerns to FIS

If you feel you are being treated unfairly, talk to us, we will do what we can. We can, through our own contacts in the industry, the CLC and contact with the Small Business Commissioners Office and Civil Service shine a light on negative trends and poor behaviour, it can be done anonymously and handled sensitively so as not to damage your relationships.

FIS is urging the supply chain to heed the advice of the Construction Leadership Council and adopt a collaborative approach and ensure that there is ongoing and open communication through the supply chain and we are doing all we can to work together rather than tearing lumps off of each other.

Too often construction get contractual and adopts a siege mentality, parcelling up and firing risk out hoping it sticks elsewhere. The much talked about transformation must start now, rather than pushing risk down the supply chain, we need to be communicating with clients, helping them to understand that these events are beyond the control of individual companies and we need to work together to resolve and manage.

Our supply chain has had an unprecedented and difficult year, we need to nurture it back to health, not return to old and punitive ways that will ultimately drive people out of business to the detriment of all.

Useful links:

FIS Webinar: Managing your business in a time of shortage – Listen again here

You can access the latest Construction Leadership Council Product Availability Statement here (27 July 2022).