Four Step Plan to Rebuild Construction

Transformation in the Finishes and Interiors Sector: Vital steps to unlock potential

FIS recently commissioned research with the University of Reading into the Procurement and Contracting Behaviours in the Finishes and Interiors Sector. The report makes gritty reading. It points to a procurement model that undermines intent and limits innovation. A model built on mitigation rather than management of risk, a broken model that, from the outset creates unequal and adversarial relationships that ultimately means we are seldom the sum of our parts. These behaviours not only limit the potential of the sector, but contribute to labour shortages and an insurance, credit and mental health crisis in construction.

FIS recently commissioned research with the University of Reading into the Procurement and Contracting Behaviours in the Finishes and Interiors Sector. The report makes gritty reading. It points to a procurement model that undermines intent and limits innovation. A model built on mitigation rather than management of risk, a broken model that, from the outset creates unequal and adversarial relationships that ultimately means we are seldom the sum of our parts. These behaviours not only limit the potential of the sector, but contribute to labour shortages and an insurance, credit and mental health crisis in construction.

Step 1: Return to the principle of unamended contracts.

In 1931 we agreed that risk should be shared fairly through the supply chain. To this end we established and set up a suite of contracts that defined the roles and responsibilities of the various parts of our industry from design through to specialist, the JCT contracts. Yet since day one we have abused and manipulated this system and now we see contracts that have reams of amendments often larger that the initial contract and invariably designed to squeeze risk down the supply chain. In a sector where margins are measly why on earth do we allow legal fees almost double the industry average to remove vital waste.

FIS is encouraging members to sign the Conflict Avoidance Pledge.

Step 2: Move to Integrated Project Insurance.

Whilst our contracts bounce risk around like a game of pinball, our insurance does little to protect or manage it. A move towards project insurance would start to ensure that risks are clearly thought through from the outset and managed throughout, ensuring that the details are considered and we move away from the Build and Design culture that we find ourselves in.

For more information on FIS Insurance Services click here.

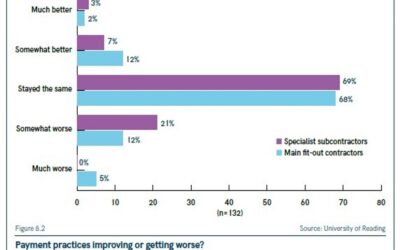

Step 3: Don’t starve the supply chain of working capital

Payment practices remain far from healthy, retentions are mismanaged and it is rare any capital is injected to support the set up of jobs. A period of “cheap money” masked the concerning consequences of this behaviour. The organisation has long advocated that the Duty to Report and the Prompt Payment Code masks what is actually happening the ground and issues associated with delaying tactics, payment applications, retention, pay less notices, certification and underpaying all of which have not been picked up in this reporting. We welcome the changes, but better data needs to be matched with tougher sanctions.

Read FIS CEO, Iain McIlwee’s article published in Construction News in December 2022.

Read the FIS Position Paper on Retentions which FIS advocates are an archaic way to manage quality and no longer fit for purpose. They undermine a positive culture in construction and engender a lack of trust.

Read more about the work FIS is doing with the Small Business Commisioner on prompt payment.

Step 4: Earlier contracting of key regulated packages is essential

The default should be two-stage tendering to ensure risk is effectively understood and work should not commence until a Stage 4 Design (on regulated) works is completed to ensure that interfaces and penetrations are assessed and all products are available, systems are buildable and performance can be evidenced. To achieve this effectively, irrespective of the adopted procurement approach, a clear design responsibility matrix must be presented and the expectation should be that any specialists and suppliers named will be those to whom the work is awarded.

Beyond the design risk, early contractual appointment will support effective workfoce planning and programming, limit buildability issues, reduce levels of rework and ensure that net zero considerations can be prioritised and social value expectations met.

Find out more about FIS work on Delivering Quality in the New Normal

New procurement rules demand faster payment on major contracts

A new stricter procurement regime is being introduced to support the Government's 2019 Manifesto...

Creating a productive environment for UK Construction

Building better: CLC announces plan to boost industry productivity by 25%. The Construction...

FIS calls for payment and retention overhaul

FIS had today responded to the Amendments to the Payment Practices and Performance Regulations...

Construction Reform: Supporting Information

FIS Blogs on this subject:

- Let’s talk about Modern Methods of Procurement

- Design Liability – Squeeze the Day

- Construction insight: Changing the narrative

- Let’s leave Contractors in the past

- How to survive in the woods: Is the construction industry in survival mode?

Constructing Excellence: How-to-Guide to Best Practice Procurement: An interesting breakdown of the pre-tender, tender and post-tender aligned to the various contractual options with some solid recommendations of best practice.

The CLC Roadmap to Recovery has laid out proposals to secure the future of construction businesses nationwide, while setting the industry on a sustainable path towards recovery based on three key steps.

- Transformation – sustain economic growth through the adoption of digital and manufacturing technologies to consistently deliver low carbon, sustainable and better-quality outputs and outcomes

- Value – adopting procurement models and approaches across the industry and clients to deliver better value and whole life performance

- Partnership – stronger partnerships between the industry and its clients, supply chain firms, investment in upskilling the workforce

This is supported by the Construction Playbook which sets ground rules for public sector procurement. It is mandatory for central government contracts to apply the rules of the Playbook (or make a clear case for why it was not feasible) and suggested for local and devolved contracts. The Playbook has no status outside of Public Sector works, but does provide a useful framework for defining “better”.

The Value Toolkit has been designed to support the Construction Playbook and contains a suite of tools in four linked modules which will:

- Support policy makers, clients and advisors in defining the unique value profilefor a given project and create value indices through which informed decisions can be made;

- Help clients and their advisers to select a delivery model and commercial strategy,and industry to develop business models, that best meet the value drivers of the project;

- Build on the groundwork laid by Ann Bentley and the Construction Leadership Council Procuring for Value Working Group and the IPA’s Transforming Infrastructure Performance to allow clients make procurement decisions based on the value drivers of the project and industry to shape their offers accordingly; and,

- Continuously forecast and measure value performance throughout delivery and operation, helping clients and industry to maximise value on each project and using performance data to help policy makers shape decisions on future projects.

World Economic Forum – Shaping the future of construction, a breakthrough in mindset and technology: A greater emphasis on planning and programme: UK public procurement takes 50 per cent longer than equivalent processes in Germany. In 2018 we built 2.25 homes per 1,000 people, Germany managed 3.6, the Netherlands 3.8, France 6.8.

Fine margins: delivering financial sustainability in UK construction: In the UK, more than 90% of construction projects experience some level of delay greater than 10% beyond the planned schedule. Most often, this is due to the cumulative build-up of a high volume of small tasks within a project each experiencing an issue resulting in a short delay. (A follow-up to this report is available here).

Gleeds: A spotlight on Modern Methods of Procurement – Contractors were asked to rank the acceptability of the procurement / tendering routes in the current market.

The Farmer Review of the UK Construction Labour Model – This review adopts a structure of evaluating the construction industry’s current and future state which has a strong medical process analogy:

- Identify the symptoms

- Diagnose the root causes

- Provide a prognosis

- Establish a treatment plan for recovery

- Keeping the industry under observation

This is the most recent in a series of Government led reviews including (HMG Industrial Strategy: Construction Sector Deal, The Egan Report: Rethinking – Constructing Excellence, The Latham review: Constructing the Team)

Supply Chain Productivity in Construction, Transforming Construction Network Plus – This digest shows how productivity improvements based on supply chain management used in manufacturing could be applied to improve the performance of construction. It presents three considerations for improving productivity in construction:

- Building end-to-end supply chain integration

- Achieving ‘economies of repetition’

- Adopting digital technologies to improve supply chain planning

Closing the Gap Between Design and As-Built Performance Evidence Review Report – An excellent example of a gap analysis style report. In February 2011, a Zero Carbon Hub task group, having reviewed historical research and gathered further industry evidence, advised that future performance standards for zero carbon homes should be linked to ‘as-built’ performance to achieve the ‘2020 Ambition’. In response to this challenge the Performance Gap project commenced at the start of 2013, bringing a wide range of participants together to establish a better understanding of the Performance Gap and to formulate any necessary solutions. The initial activities and findings are detailed in the Interim Progress Report, published in July 2013.

The Building Safety Act is the largest overhaul of Building Regulations since 1666! It introduces a new regulator, gateways and a greater emphasis on accountability and competence. Will it help to drive cultural change? Instrumental reports into the shaping of this Act include:

- Dame Judith Hackitt’s final report, Building a Safer Future: Independent Review of Building Regulations and Fire Safety

- Dame Judith Hackitt’s interim report: Independent Review of Building Regulations and Fire Safety

- Setting the Bar – The second and final report of the Competence Steering Group [CSG] and is an update of its Interim Report, Raising the Bar, published in August 2019. The work was initiated by the recommendations in Dame Judith Hackitt’s review Building a Safer Future.

Guide to Contract Alliancing in Construction Alliance Models – the Alliancing form of contracting has been developing since recommendation in the Latham report. It remains rare in the UK, but according to this report by Arcadis it is now gaining increasing traction in a number of countries around the world and its popularity is growing.

Strategy for Change – Get it Right Initiative (GIRI) first piece of work to identify both the most economically significant errors and their causes. Key international studies suggest that the measured direct costs of avoidable errors are in the order of 5% of project value. This equates to approximately £5 billion per annum across the sector in the UK and is higher than average profit levels across the industry (around 3%). The latest revision is available here.

Constructing the Gold Standard – An Independent Review of Public Sector Construction Frameworks – This review shows how clients and suppliers can create and implement a Gold Standard framework alliance contract which includes:

- An outcome-based strategic brief that drives economic, social and environmental value with strategic supplier proposals for delivering that brief

- Multi-party relationships that align objectives, success measures, targets and incentives with commitments to joint work on improving value and reducing risk

- A timetable of strategic actions to improve integration, value and outcomes, for example using MMC, digital technologies, ESI and Supply Chain Collaboration

- Transparent costing, call-off, performance measurement and incentives that provide a fair return for suppliers and drive value rather than a race to the bottom

- Framework management systems that support collaboration and dispute avoidance

Harnessing the Data Advantage in Construction – Global gross domestic product (GDP) in 2020 was $84.5 Trillion …and construction accounted for 13.2% of the Global GDP in 2020, roughly $11.15 Trillion …but Bad Data may have cost the global construction industry $1.848 Trillion in 2020. Additionally…bad data may have caused 16% of all construction rework globally in 2020* …bringing a rework cost of $88.69 Million worldwide.

- The volume of available project data has doubled in the last 3 years

- One third of all poor decisions were made as a result of bad data

- But an alarming number (30%) shared that over half of their data is bad

Quality Management: A number of reports have been written that look at the causes of error in construction: Two that stand out are: Report on Edinburgh schools and Closing the Gap Between Design and As-Built Performance Evidence Review Report

The University of Reading, Finishes and Interiors Sector (FIS) and AMA Research (part of Barbour ABI) have publiahed a report on New in-depth report puts procurement practices in the finishes and interiors sector under the spotlight – FIS (thefis.org) aiming to better understand how procurement practices are affecting the £10 billion fit-out industry and most importantly, how they can be improved.

better understand the evolution of procurement practices, the organisation commissioned Professor Stuart Green of the University of Reading to explore procurement practices in the UK fit-out sector. FIS has a close working relationship with AMA Research, who were also keen to explore this topic and support this work and were able to offer assistance in developing the survey and extending the reach for participation.

This result is a fascinating new report that benchmarks current practices from those contractors directly involved and explores how procurement impacts effective delivery. Through better understanding of the challenges facing the industry, the sector can deliver better value and improve supply chain relationships.

See all our campaigns

To find out more about how you can benefit from FIS Membership, click here.